Adding value to the supply chain with Smart ecoDesign ©

Eco-Design Case Study by the Centre for Sustainable Design (CfSD):Crawford Hansford & Kimber (CH&K)

|

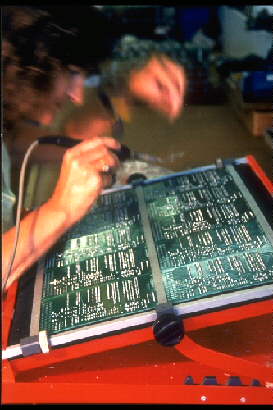

When John Simmonds surveyed the prospects for his 30-strong company, Crawford Hansford & Kimber (CH&K) - designers and manufacturers of electronic and electrical equipment , including printed circuit boards (pcb's) - he was not in his most positive state of mind. But that was in 1997; factory prices were dropping, salaries and property costs rising. At the same time the sector was under pressure from proposed legislation, which was threatening to curb use of lead and other substances used in products. A further pressure - to keep prices under very tight control - came from customers who were keen to leverage advantage from their supply chains. "This combination of factors pointed to difficult times to come," says Simmonds, MD of Farnbrough (Hants) - based CH&K." But for us they were the drivers of an 'eco-design' initiative that would see us adding value to the supply chain and working with the customer - a large manufacturer - to reduce costs." The initiative that transformed the landscape for Simmonds had its origins in The Centre for Sustainable Design (CfSD), based in the Surrey Institute of Art and Design, University College. There, Martin Charter, Visiting Professor in Sustainable Product Design, masterminded a training campaign directly aimed at SME's, the focus of which was the proposed European Directives called WEEE (Waste from Electrical and Electronic Equipment), and Restriction of the Use of Hazardous Substances in Electrical and Electronic Equipment. These proposed directives will require the substitution of lead (among other things) by 2008. The training campaign, part of the ETMUEL (Eco-design Training for Manufacturer, Use, End of Life Management) initiative, was also targeted, indirectly, at SME's through large company supply chains, such as Cable & Wireless. "We saw an opportunity to get SME's involved by taking a new look at their design and production processes," says Charter. There was a catch, and it was WEEE's list of compliance requirements, which electronics and electrical equipment companies would have to comply with in the new century. Says John Simmonds: "The Centre simplified things for us with an ETMUEL eco-design checklist and provided training in how to incorporate environmental aspects into the design of new products and processes". The training, it turned out, was a key to the success of the project. At first there was some scepticism of the project from staff. "They saw WEEE as just another bit of regulation, but when they studied the ETMUEL list they could see how it could be used to help us gain competitive advantage. WEEE is designed to 'clean up' products manufactured by SME's, through substitution of the use of toxic substances; by acting early in the cycle we recognised we could be an early player with 'cleaner' and possibly better technology." Another dynamic was the move by large manufacturers to increasingly outsource production of items like pcb's. "This trend has led us to better managing the supply chain and we can now see how we can add value to the supply chain and be a more significant player in it - a company to be noticed and to do business with," says Simmonds. Indeed, he recognises that eco-design can happen through persuasive forces in the supply chain. "CH&K sits in the middle of a complex supply chain and can now influence the 'eco' thinking in the upstream of the supply chain - our suppliers - as well as the downstream - our customer. And finally, another driver of change was the speed of technology innovation. "By seeing how pcb-based products could be re-designed we would be speeding our own take-up of innovation and producing an improved product." A crucial turning point came when CH&K found a customer - Hilton, suppliers of data logging and other instrumentation to the education sector - which was interested in participating in the project. Hilton agreed to work with them to see how prices could be brought down. Another piece of the jigsaw fell into place when one of Simmonds' suppliers - Eurotech P.C. Ltd - agreed to work with his company on a new design of a pcb that would comply with WEEE. "Like us, Eurotech was aware of the planned legislation and were keen to work with us on a partnership basis to create a new type of pcb. Benefits: "A new pcb design can precipitate a number of benefits that are waiting to be taken up," says Simmonds. These benefits include the use of new materials in the outsourced printed circuit board base; new track design; the reduction in the chemicals used in the production process; and the substitution of lead by organic silver in the soldering process. A further benefit will come if the sourcing of 'cleaner' components - which do not incorporate lead or other to-be-substituted substances - can be realised. Other benefits include innovation and increased competitiveness. "The eco-design checklist can act like a catalyst, influencing the way you think and design," says Simmonds. "A prime influencer behind WEEE is that environmental factors have a high profile - you have to take notice of them. Focusing on the environmental aspects of a product makes you start asking questions of suppliers and customers in the supply chain, and this questioning can drive innovation. The result of that can be products that give a real competitive edge, such as adding value in the supply chain, as we have done." Steve Scarlett, Technical Manager of CH&K, enthused about the benefits of the project. "Perhaps the main benefit from my viewpoint is educational. We learned that lead can be eliminated from the solder and the use of acid wash greatly reduced during pcb production. "In addition, we know that the pcb is more easily disassembled to its component parts at its end of life, making it easier to recycle. It can now be disassembled with one screwdriver." Importantly, we eliminated lead from the solders and paid nothing for this benefit because the replacement cost no more. In fact the entire new pcb was produced at no extra cost. Low flux soldering with organic silver proved not to be a problem; introducing it was a completely painless process. We also reduced the number of mechanical fixings, so lowering the cost." In addition, the project has been beneficial to Eurotech. By removing lead from PCBs, Eurotech can now apply an in-house treatment process instead of paying a subcontractor to remove the hazardous waste after the PCB etching process. In addition, the treatment process allows the recovery of nearly all of the copper dissolved in the solution, which can then be reused or sold. There is an obvious environmental benefit in this, as well as a financial one for Eurotech. One big benefit to CH&K: Steve Scarlett has learned where the company needs to carry out further research and possibly implement further projects. However, there is a big benefit down the line, "when major customers in supply chains start to demand 'cleaner' products - we will be better placed to supply them." An immediate, shorter term commercial benefit is that CH&K hopes to supply, to schools, power supplies that are produced with reduced lead content - a direct result of the ETMUEL project. Richard Hall, an ETMUEL project trainer in eco-design, helped Simmonds' team with hands-on training in the ETMUEL eco-design checklists. "This training was very important to us because the checklists are long and need to be explained well and in the context of our business," said Scarlett. "Without the training I am not sure the project would have got off the ground." But this training has brought benefits to CfSD as well. A training partnership between CH&K and CfSD has been established and this has resulted in a mutually beneficial learning experience. According to Aleksandra Kielkiewicz-Young, a researcher at CfSD who works closely with CHK: "On the one hand this training has developed eco-design competence and capacity in CHK, and on the other it has allowed CfSD to carry out research to better understand the "hands-on" eco-design process. That is, CfSD better understands the real needs in the electronics sector - including issues in the supply chain. This understanding will allow CfSD to develop the most appropriate tools, which will facilitate the rollout of the eco-design process in the electronics sector." Conclusion: The result of the project is a "cleaner" pcb that is now is use at three locations in higher education around the world. It is incorporated into equipment that interfaces with data loggers - part of a thermal management system designed by Hilton and used as part of a degree course in thermal management. Within CH&K, the project has proved a popular one after the initial scepticism. "At the SME level, not every company will want to do what we have done as it requires investment in time and, to a lesser extent, money. But having embarked on this way of adding value to the supply chain - by offering our customers something they don't have - we want to stay with it and further increase our competencies in a number of areas in sustainable product improvement. "It would not have been possible to make it happen without help from The Centre for Sustainable Design; their assistance with compiling the compliance checklist and in training was vital to the success of the project." Now, John Simmonds can look ahead with renewed confidence. Not only does he have a new product and process on his hands, but his company is a member of the Farnborough Aerospace Consortium - and Farnborough is going to be home to Europe's largest science park. This means a larger customer base - and customers who may be keen to partner with him in continuing to pioneer cleaner product development. "We plan to grow our influence in the supply chain. CH&K now has an environmental awareness - and knowledge of eco-design - that we did not previously have and I believe we can exert a positive influence on other companies." For CH&K, this has definitely not been a "one-off" project. The company is now using the knowledge it has gained, in a new contract which it won partly because of its eco-design capabilities. "Although the legislation is not yet in place, those companies that take its lessons on board will gain competitive advantage," says Simmonds. Case Study written by:

Paul Whitehead For more information on ETMUEL contact: Martin Charter at the Centre for Sustainable Design or mailto:[email protected] |